Weekends Only exists to provide quality and affordable furniture for every home and budget. Since opening its first store in 1997, Weekends Only has grown to be one of Furniture Today’s Top 100 U.S. Furniture Stores. With 50,000-square-foot showrooms, the organization offers customers the live experience of browsing, feeling, and testing combinations of furniture sets with certain functions of interest: dining, living, bedroom, recreation, etc. Weekends Only also entered the online shopping market in 2013 with its e-commerce website functioning 24/7.

As its name suggests, the Weekends Only showrooms are open only during the weekend: Friday, Saturday, and Sunday. The organization spends the rest of the week sourcing the best deals nationwide for their customers. This unique business model drives down operational costs, keeping the price tag low for customers. Weekends Only also facilitates a new hybrid click-and-mortar model, taking advantage of both the convenience and accessibility of e-commerce and the personal shopping experience of a brick-and-mortar store.

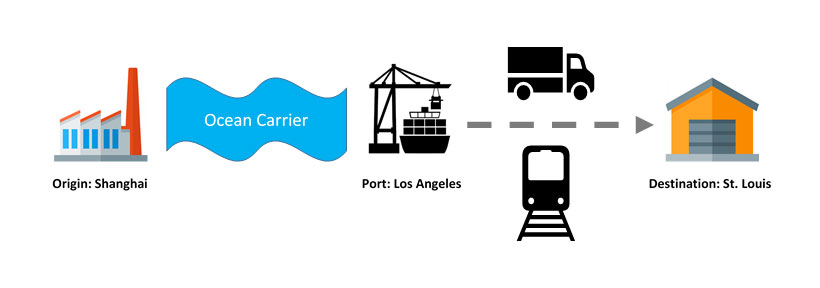

A top priority among Weekends Only’s operational challenges is to continuously optimize the distribution of procured furniture from vendors all over the world, as well as optimize transportation routes to its warehouses and retail stores in the US. Historically, inbound ocean freight from Asia had been shipped via the Port of Los Angeles in California. However, recent developments have made the Port of New Orleans and the Mississippi River potentially attractive options.

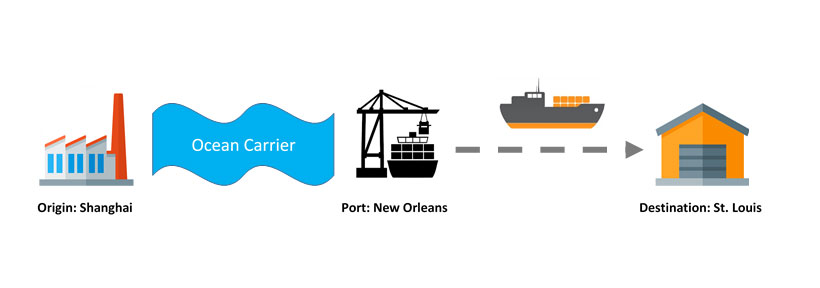

The logistics team at Weekends Only wanted to explore the cost-benefit of multi-modal transportation, via a combination of ocean, barge, and truck, through the Port of New Orleans and the Mississippi River. Specific interests included determining under which conditions (cost factors, lead time, capacity, etc.) should Weekends Only opt for with this alternative transportation route or combination of routes.

In collaboration with the University of Missouri-St. Louis, Weekends Only chose the anyLogistix platform to take on their supply chain challenges. Their choice was quickly justified, as anyLogistix was the only software package on the market that could comprehensively model their transportation requirements by combining both optimization and simulation modeling methodologies in one platform.

Within the anyLogistix solution, the team was able to model and experiment with two core scenarios, current state and potential future state.

Figure 1. Current transportation route at Weekends Only

Figure 2. Alternative shipping route/mode from Shanghai to St. Louis

Considering various constraints Weekends Only sought to determine:

Leveraging the anyLogistix Network Optimization & Simulation capabilities, Weekends Only could determine that the Port of New Orleans was an utterly attractive option for transporting their inbound freight. Annual cost savings identified by the project were roughly $730,000, or 27% of their total Shanghai to U.S. inbound freight expenditure.

To mitigate risk and ensure the route change decision was best for the business, a series of simulation experiments within anyLogistix were performed. Using anyLogistix software for transportation route optimization, Weekends Only could holistically demonstrate that the slight increases in lead-time and required landed inventory were more than offset by the transportation savings and trip frequency reduction, leading to an across-the-board project success.