The causes of the bullwhip effect in a supply chain can be very different. The main reason for the bullwhip effect is the demand and supply uncertainty. The phenomenon is called a bullwhip because even small changes in, for example, demand for goods can cause a snap in the demand for details and raw materials further down the supply chain.

Understanding the bullwhip effect helps secure your supply chain. It is difficult to predict the complex interactions of inventory plans, sourcing policies, and demand variability when even small events can cause significant disruption. With simulation modeling it is possible to capture business processes and operations across multiple tiers to create a supply chain digital twin that can quantify the bullwhip effect.

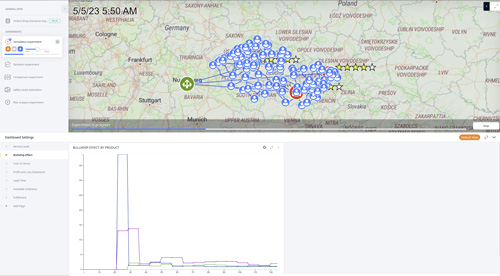

With the anyLogistix (ALX) supply chain design and simulation tool you can account for the bullwhip effect in your network, identify its causes, test different scenarios and find the best mitigation policies. Demand modeling and forecasting can make you supply chain more reliable and resilient.

To do this, ALX enables you to:

By using simulation modeling, ALX makes it is possible to capture and evaluate the details and behavior of your supply chain as in reality, including the uncertainties and random events that can lead to the bullwhip effect. This model can also be combined with current operational data to create a digital twin of your supply chain for up-to-date diagnostics and forecasting.

Important factors that can be captured include:

To learn how simulation can help you quantify the bullwhip effect and make a supply chain more resilient, read the Supply Chain Simulation and Optimization book. It explains how to use anyLogistix to create supply chain models, conduct experiments and analyze the results. You can also download the free version of the anyLogistix software right now and start experimenting.

The bullwhip effect is about uncertainties and random events. So, one of the most important questions for supply chain managers is how to reduce demand uncertainty.

To quantify demand variability in supply chain, you need to represent your supply chain in a dynamic simulation model, see the inside interactions in motion, and measure their results. Traditional analytical supply chain design tools cannot do this.

ALX is the only supply chain planning software tool that provides a range of simulation modeling capabilities, including agent-based modeling. With ALX, you can: