The complex nature of modern supply chains makes them more efficient and effective than ever. At the same time, their elements are much more interdependent, which makes supply chains less flexible and more vulnerable to disruptions.

Companies struggle to make their supply chains resilient — to be both low risk and able to adapt quickly to disruption. Optimization and simulation modeling are proving to be the best supply chain risk management solutions to help achieve supply chain resilience and reliability.

To learn more about how optimization and simulation modeling can help deal with uncertainties and supply chain disruptions, read the Managing Risks in Supply Chains with Digital Twins and Simulation white paper or watch the issue-related webinar.

Risk analysis is the process of identifying and analyzing potential issues that could negatively impact key business initiatives or critical projects in order to avoid or mitigate such risks.

Thus, we can distinguish three main stages:

For a deeper dive into supply chain risk analysis with the anyLogistix software, watch the following how-to video. Using the example of a shoe supplier working in Vietnam and Japan, the video explains how to stress test the supply chain in emergency situations with the Risk Analysis experiment in anyLogistix.

Supply Chain Risk Analysis

We can classify supply chain risk mitigation strategies into reactive and proactive.

The goal of proactive strategies is to avoid supply chain disruption or reduce the future probability of the undesirable effect. You could also call this type of strategy predictive or preventive. Reactive strategies, on the other hand, involve actions in response to something.

It is important to realize that, in real life, it is all about the balance of proactivity and reactivity in your supply chain risk management. Any large company takes some actions to prevent damage from a supply chain disruption. At the same time, since it is impossible to predict everything, companies must be ready to respond quickly and efficiently to the consequences of disruptions.

Proactive risk management involves assessing existing business processes to determine the potential risks, assessing probability and impact to prioritize risks, and accordingly preparing a contingency plan.

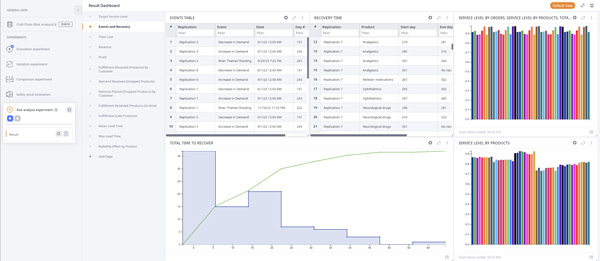

anyLogistix combines analytical tools for network optimization with a unique dynamic simulation engine. Using these techniques together, it delivers more accurate and transparent decision-support models, allowing for more efficient supply chain risk analysis.

The anyLogistix software offers the following workflow to perform supply chain risk analysis:

When something already happened and a supply chain performance is already disturbed, a reactive risk management strategy comes into play. In such situations, you do not have too much time to get all possible data, analyze every detail, and come up with a plan. More often, these mitigation plans are created quickly and under the pressure, so they cannot take into account all the details of the situation. Sometimes these plans are more of a guess than a tested and proven hypothesis.

Reactive Risk Management in Supply Chain

Still, there is a way to become more prepared for any disruption — create a digital twin of your supply chain. A digital twin is a detailed simulation model of your supply chain. Using real-time data and snapshots to forecast supply chain dynamics, a supply chain digital twin can help you quickly come up with action plans to help you address abnormal situations, and test your plans to ensure they are effective. Moreover, digital twins can send notifications and alarms when disruptions occur. So, if something happens, you will be immediately informed and will be able to respond quickly and effectively. Having a digital twin of the supply chain will greatly simplify the creation of mitigation plans and will allow you to quickly test their effectiveness before implementation. Learn more about supply chain digital twins >>

Risk Management with Supply Chain Digital Twin

To sum up, by using the anyLogistix Simulation and Risk Analysis experiments you can stress-test your supply chain in emergencies, analyze the results, and implement the necessary changes to make your supply chain more reliable and resistant to disruptions. Thanks to anyLogistix visualization capabilities and advanced statistics you can get a detailed and clear visual representation of any metric you need. So, you can easily analyze the results of the experiments and measure the possible consequences of every supply chain disruption. Moreover, with anyLogistix you can create a digital twin of your supply chain, which will help you to respond quickly and effectively to any disruption.

To find out more about anyLogistix features and decide how they can be useful for you, read the technical datasheet or download the free version of anyLogistix software.