Excel is widely used by companies, large and small, for supply chain network design, optimization, and planning. Analysts use it to address a range of common supply chain management challenges:

These common challenges are met using optimization techniques such as linear and mixed-integer programming, as well as heuristics.

As the scale and complexity of supply chain models grow, Excel becomes insufficient for these challenges. As a result, many companies switch to R or Python, or even to working directly with optimization solvers. This approach may be more capable, but it can pose difficulties acquiring and transferring the required skills within the company.

For large-scale, data-intensive problems that require complex model logic, true supply chain leaders go with specialized managerial tools. anyLogistix provides optimization, based on CPLEX, and simulation, based on AnyLogic, in an easy-to-use supply chain modeling framework. Easier to use than Excel and with all the power and flexibility of a custom-made solution.

try now

Almost every company working with supply chain optimization in Excel at some moment faces an Excel error leading to a managerial mistake. This is because Excel models in essence are just huge spreadsheets full of formulas – these models are hard to build from scratch, and even harder to extend and maintain. An error in a single cell is very difficult to trace and can lead to millions of dollars lost.

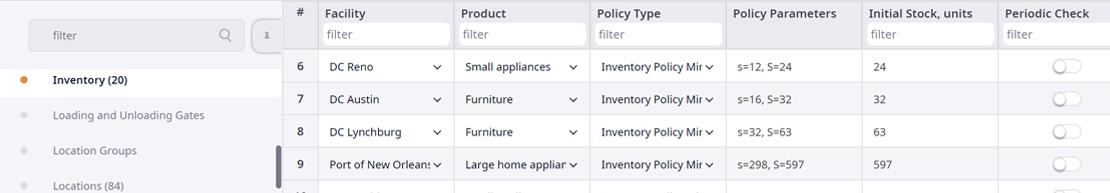

In anyLogistix, many supply chain constraints and decision variables are pre-set, so they are easier to create and sustain. This also opens up the possibility for input data validation and error tracing, in case of problem infeasibility. In addition, anyLogistix has a map editor with a network structure view that can help detect many input or output problems visually.

Optimization in Excel requires knowledge of linear programming. Custom scripting would in addition call for language syntax skills. With these tools, it may be hard to get started with optimization, not only for you, but also for your teammates and stakeholders: it can be tricky to get around in a supply chain model that someone else has built because it only consists of code and formulas.

With anyLogistix, you work not with abstract constructs, but with supply chain settings. For example, you drag and drop customers and DCs on a map, visually set products and periodic demand for them, and add storage constraints and vehicle types. In minutes, you’re ready to run your first optimization! It is intuitive for a manager with no extensive tech or math background, so they can focus on working with logistics data, and not the tech side.

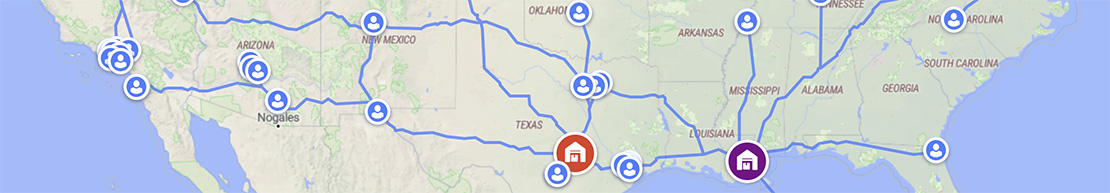

Modeling with spreadsheets and scripts means that you never get to visualize your supply chain network properly. The inputs and results you receive are just variables and their values, and it’s easy to get confused looking at large datasets. So, you end up questioning, what would this model output look like “in the field”?

anyLogistix presents your network on a map, so models are easier to build, verify, and understand. What is more, map data helps speed-up your work: road distance data is calculated automatically and you don’t need to manually load it into the model.

Some supply chain managers are tired of maintaining their cumbersome Excel spreadsheets, but still, they stay away from specialized supply chain tools. The reason? They are worried about losing the flexibility of their bespoke solution.

anyLogistix is an extendable tool where you can enjoy pre-built model templates, logic, and statistics that save your time without sacrificing flexibility. Besides standard functionality, you can set custom constraints, add your own decision variables, and modify objective functions, all in the familiar form of linear inequalities, as used in Excel and linear solvers.

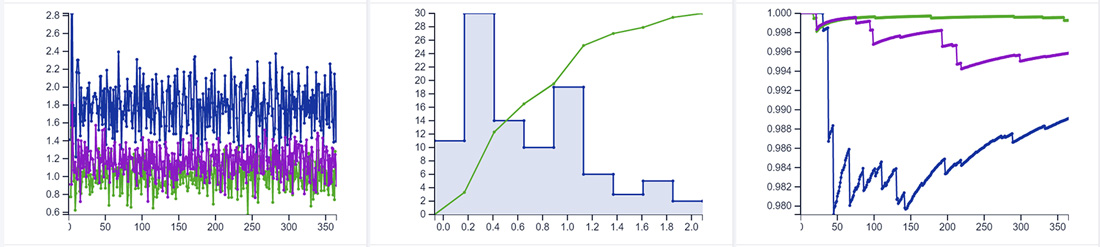

Many optimization users underestimate the power of simulation. Simulation is not just a replacement technology, it is a technology that helps resolve a greater set of challenges. It’s the next step that lets you go deeper with your analysis, as it adds process logic, time, and randomness into a model. You can’t do these things with Excel, and until now, you would have needed to learn a specialized simulation tool.

anyLogistix goes beyond optimization, it has a customizable simulation engine underneath, it’s two technologies in one tool. And, for inventory and sourcing management, risk analysis, and resilience planning, simulation provides more value than optimization.

Get a competitive edge by switching to a more capable prescriptive analytics tool for supply chain — anyLogistix.

get started