Supply chain operations are exposed to many risks, and research shows that supply chain managers spend 40-60% of their work time handling disturbances. This need not be the case. Enhanced understanding, planning, and management can minimize the costs of risk and maximize business objectives.

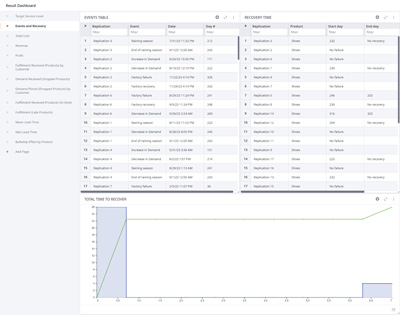

anyLogistix (ALX), supply chain risk management software, is a handy platform for supply chain risk assessment. It allows users to replicate a supply chain network and simulate its operations, making allowances for the uncertainties and stochastics of the real world. This is achieved with ALX simulation modeling technology and cannot be done using traditional analytical supply chain risk management tools. In addition, simulation in ALX allows users to test multiple network or policy change scenarios to increase the supply chain resilience and define contingency plans.

Data reflecting the status of a supply chain can be fed into a simulation model to create a supply chain digital twin. This enables quick and informed decision-making when it is needed most — as a situation is developing. With ALX, supply chain risk mitigation is achieved not only with planning but also through effective response.

Learn more about how simulation modeling is proving to be the only way capable of dealing with uncertainties. Read our white paper, Managing Risks in Supply Chains with Digital Twins and Simulation, about supply chain disruption, ripple effect, mitigation strategies, and the supply chain resilience concept or watch our issue-related webinar about risk management in supply chain.

It is important to notice that ALX is able to handle both operational and disruptive risks. Let us examine what is the difference between these two concepts and why it is so important for the effectiveness of risk management in your supply chain.

Simulation modeling in ALX allows you to include randomness in your supply chain model. By running the model multiple times, with varying parameters, you can see how instability can affect supply chain operations. This enables you to assess risks quantitatively, calculating the both the event’s probability and its associated losses.

Estimate supply chain operational risks, such as:

What-if scenarios enable you to stress-test your supply chain in emergency situations. The flexibility of ALX allows you to simulate any disruptive event and see how it would affect your company. For instance, test your supply chain’s resilience to:

For a deeper dive into supply chain risk analysis with anyLogistix, you can watch the following how-to video.

Having quantified the risks, you can design a network that both minimizes possible losses and advances business objectives. ALX facilitates risk management in supply chain, informs decision making and enables you to operate a lean and resilient supply chain.

Looking for ways of mitigating supply chain risks? Start building your supply chain model with anyLogistix software.

try alx