Meeting customer demands is harder than ever—and slow, rigid supply chains can’t keep up. In this post, we look at how an agile supply chain helps businesses stay flexible and improve customer demand planning. Plus, how tools like anyLogistix make it easier to adapt fast and deliver smarter.

Read more

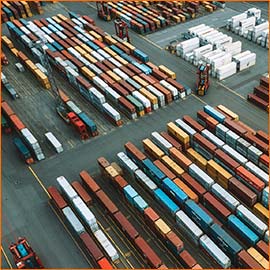

Tariffs play a huge role in global trade, affecting everything from product pricing to supply chain decisions. But managing them doesn’t have to be a headache. In this post, we’ll break down what tariffs are, why they matter, and how to calculate them in a way that’s simple and practical. Plus, we’ll show you how anyLogistix makes handling tariffs easier—so you can keep your supply chain running smoothly without getting lost in the complexity.

Read more

Explore how effective inventory planning with anyLogistix can streamline your operations and reduce costs. Delve into the best strategies, like choosing inventory policies to optimize your supply chain and support the decision-making process. Our blog post provides a detailed look at optimizing inventory management for better business outcomes.

Read more

Explore the future of supply chain management with our latest blog post on the top 5 trends for 2024. Learn how artificial intelligence, digitalization, and platforms like anyLogistix are revolutionizing the way supply chains are managed, which makes them smarter, sustainable, and stable.

Read more

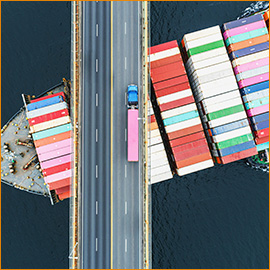

In the wake of COVID-19 and widening geopolitical risks, companies around the world are aiming for supply chain agility, resilience, and efficiency, but how can they achieve these? In this blog post, you’ll learn about current supply chain risks, what constitutes an agile and resilient supply chain, and how to achieve that through digital transformation.

Read more

When two companies join together in a merger, or one company takes over another company in an acquisition, there are many elements that need to be considered. One of the most important is the supply chain of the two companies. For supply chain synergy in mergers and acquisitions to be created, management from all departments must work with supply chain managers to develop a new supply chain that will add the most value to the business.

Read more

S&OP aligns supply chain operations with consumer demand. Although it can be highly beneficial, its implementation is not mandatory for all businesses. Companies with complex supply chains and unpredictable demand may benefit greatly, but smaller businesses could start by focusing on digitizing supply chains and leveraging optimization and simulation tools.

Read more

Governments have been trying to come up with a solution to climate change and increasing greenhouse gas emissions for years. However, their success has been limited. So, it is time for businesses and individuals to take the reins, and one way to do that is through implementing green practices in supply chain management.

Read more

Successful supply chain management is impossible without proper planning. However, supply chain planning is not as easy as it sounds. In this blog post, you will learn about various supply chain planning challenges on strategic, tactical, and operational levels, and dive deeper into planning done with modeling.

Read more

anyLogistix is used not only for business challenges but for academic purposes as well. Two students, Kunsh Puranik and Jiwon Suh, won first place along with a $3,000 scholarship prize using anyLogistix at The 2022 Supply Chain Sustainability Hackathon.

Read more