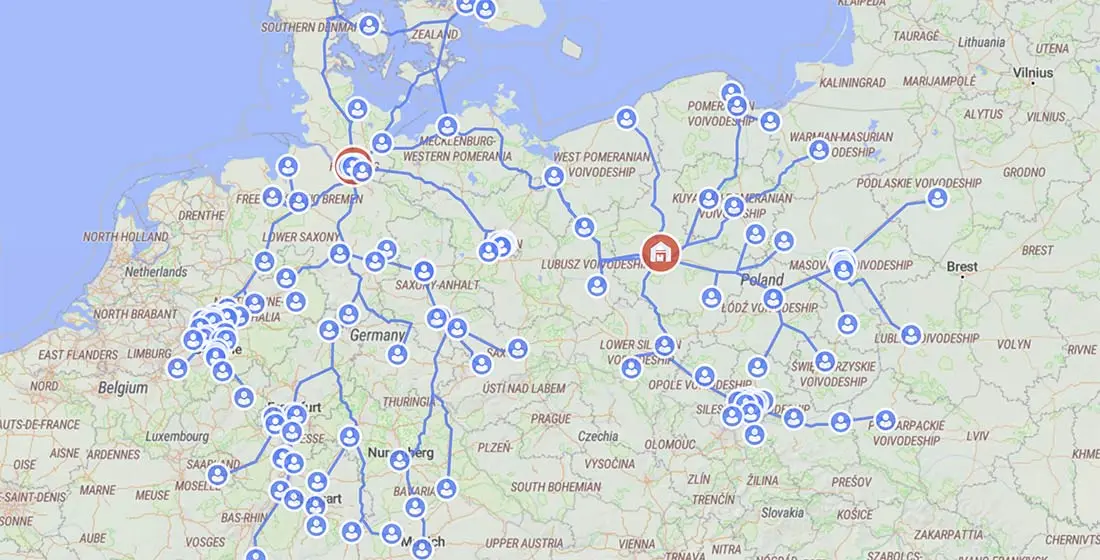

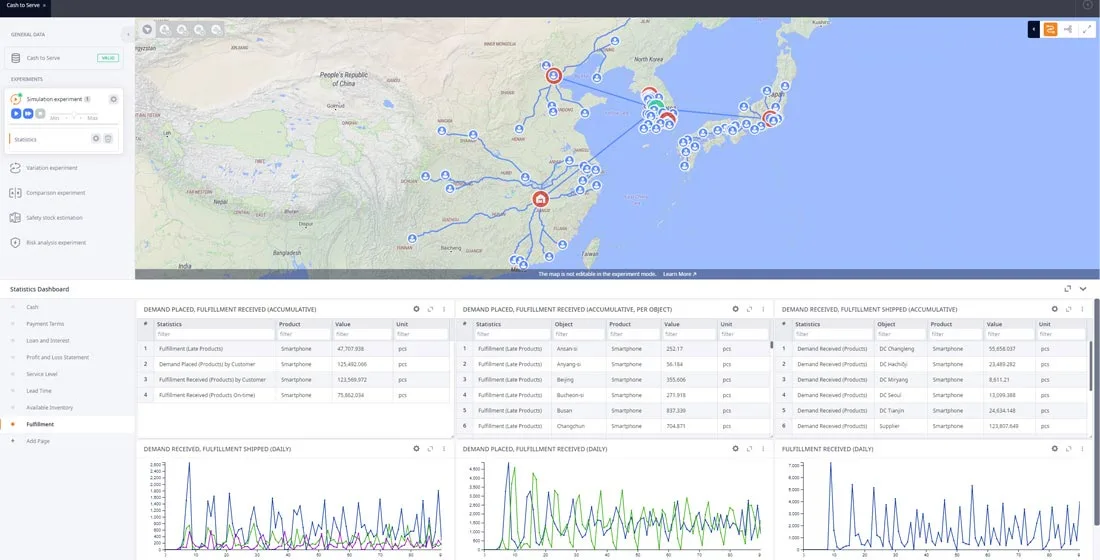

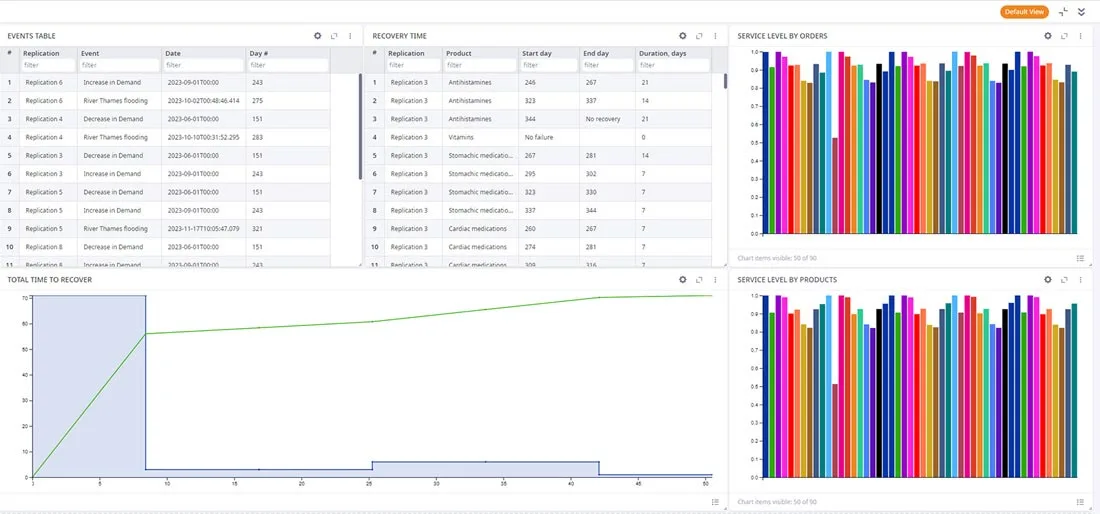

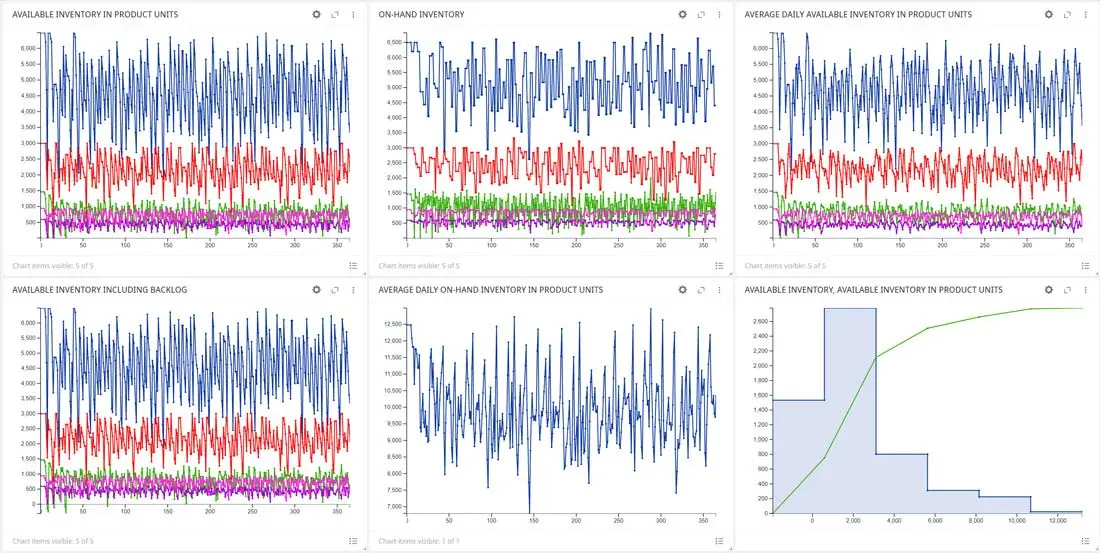

anyLogistix is the supply chain analytics software to design, optimize and analyze your company’s supply chain. It combines powerful analytical optimization approaches together with innovative simulation technologies offering you a comprehensive set of tools for end-to-end supply chain analytics.

By leveraging both simulation and optimization methods you are never limited by the lack of modeling technology when approaching a supply chain problem, further enabling you to gain deeper insights into your company’s supply chain which are not possible with traditional solutions.

anyLogistix is the supply chain analytics software to design, optimize and analyze your company’s supply chain. It combines powerful analytical optimization approaches together with innovative simulation technologies offering you a comprehensive set of tools for end-to-end supply chain analytics.

By leveraging both simulation and optimization methods you are never limited by the lack of modeling technology when approaching a supply chain problem.