A Supply Chain Digital Twin is a detailed simulation model of an actual supply chain which uses real-time data and snapshots to forecast supply chain dynamics. From this, analysts can understand a supply chain’s behavior, predict abnormal situations, and work out an action plan.

A supply chain digital twin can be used for:

In our white paper, Supply Chain Digital Twins, we investigate how digital twins and control towers are resolving challenges in supply chain. Read the white paper and estimate the value digital supply chain twins can offer your business!

read the white paper

To gain greater insight into trending topics such as digital twin and control tower, you can watch our webinar. In this webinar we explain what a digital twin is, and how it can be used to create supply chain control tower.

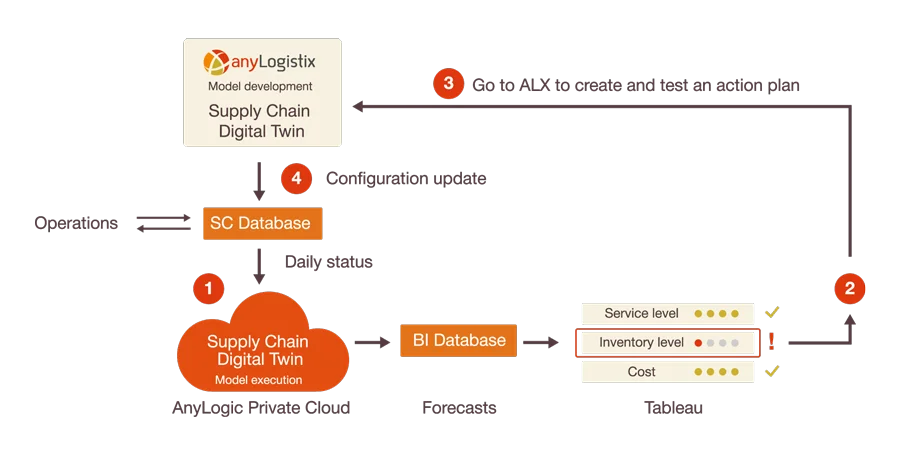

A supply chain digital twin does not stand alone. It integrates with company systems, uniting data flows and stores, and provides users with a universal window on supply chain workings. To build a digital twin of your supply chain, you need to use a flexible, scalable, and interoperable supply chain software.

anyLogistix (ALX) provides a platform to create your supply chain digital twin and enhance your operational and tactical decision making. anyLogistix integrates with all kinds of Enterprise software, including:

A more detailed example of how these tools can be integrated can be found in the white paper.

An example of the internals of a supply chain digital twin. For more details read the white paper.

Create a digital twin of your supply chain with anyLogistix for supply chain oversight, powerful analytics, system testing, and development experimentation. To start off, read the white paper or start building your supply chain model.