Sustainability has become an increasingly pressing issue in supply chain over the last few years. Rethinking and re-planning the activities of companies from a sustainable perspective is no longer a voluntary choice – they have become a duty – and companies are now called upon to question their environmental impact.

Sustainability is now a factor in all business decisions concerning supply chain activities and processes, and not just in terms of the environment. Commonly known as Sustainable Supply Chain (SSC), where transparency and sustainability are keywords and fundamental components of new business strategies. This new direction carries a twofold advantage for companies: it allows them to structure and manage a sustainable, efficient, and responsive supply chain, as demanded by customers, and it ensures a resilient supply chain network.

As evidence of the rapid evolution of a market-oriented towards sustainability, in just a few years, numerous international and national guidelines have been defined and implemented for measuring environmental performance: the ISO 14001 standard, the EMAS scheme, and the GRI 4.1 guidelines, to name a few.

Rapid changes in the business environment push managers to study competitors and defend market share. These changes, such as those regarding sustainability and social responsibility, increase complexity in company systems and the wider environment. In this regard, the use of simulation provides a systematic approach to typical supply chains challenges.

Simulation is different to traditional analytical tools and methods such as spreadsheets and linear programming. It is dynamic and provides greater opportunities for supply chain network design, analysis, and optimization. A supply chain simulation represents the logical rules of a network and, by allowing them to execute and interact over time, gives a dynamic representation of the supply chain network full of detail about the relationships between each element of supply chain network. The method can capture more detail and give deeper and more easily understood insights .

In this case, supply chain simulation allows the consideration of both traditional performance indicators and new objectives oriented towards sustainability. The approach models reality according to the desired level of detail using different variables. Specifically, simulation succeeds in describing how these variables behave and interact over time, giving insight into their causal relations.

As an example, the following are some action areas in which simulation can be applied effectively in the sustainability field:

Several advantages come from employing simulation for analyzing supply chain environmental sustainability, including:

In Italy, the food sector, which includes agriculture, the food industry, and distribution (including HORECA), is one of the country’s leading economic sectors with revenues over 500 billion euros. At the same time, it is also one of the most polluting. Estimates suggest that, overall, the sector is responsible for a quarter of the total CO2 equivalent emissions produced by human activity, of which more than half comes from meat production. In addition, the agri-food sector also causes several other environmental issues:

Action is necessary, as demonstrated by the European Commission itself by launching the Farm to Fork (F2F) strategy. The goal is to turn the eurozone, including its food sector, into a model of sustainability. In this respect, this blog highlights possible improvements in the environmental performance of companies by acting on a company’s business strategy and showing the importance of supply chain sustainability.

More specifically, the case study focuses on the yogurt sector, which since 2020 has been giving increased attention to sustainable development, focusing mainly on the recyclability of the packaging used.

The approach used in the case study is based on research and on the formulation of hypotheses necessary to create an initial scenario and subsequent improvement intervention scenarios. These scenarios are the result of development undertaken in supply chain simulation software anyLogistix.

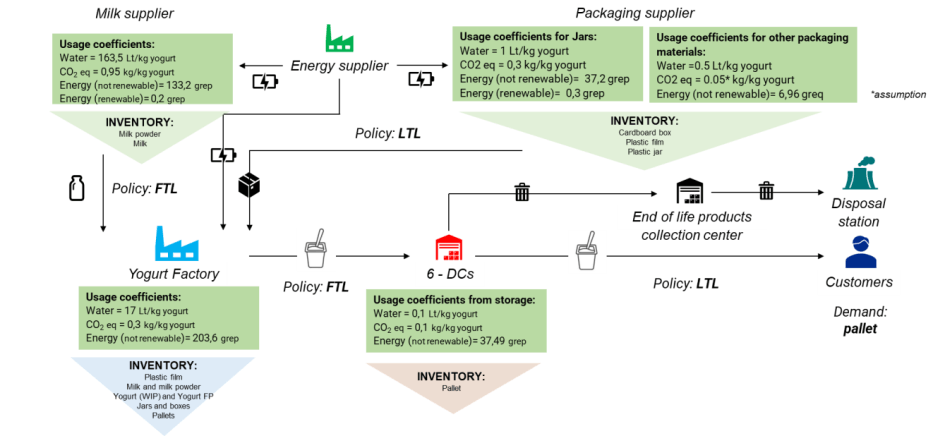

For supply chain sustainability, software tools offer many possibilities. The starting case accounted for the following items:

The improvement strategies streamline the supply chain—replacing the materials used for primary and secondary packaging, and implementing production interventions that reduce the consumption of energy, water, and raw materials.

The improvements achieved with the alternative scenarios may not be valid globally; none of the proposed strategies should be considered the only viable solution. On the contrary, the results demonstrate how sustainability decisions must often consider all other impacted performance areas. With such an approach, the role of simulation clearly emerges as the most suitable.

This blog is exploratory, descriptive, and explanatory. The strategy and the approach used can be repeated for other interventions of the same type and need adaptation only according to the sector considered and the desired performance objectives.

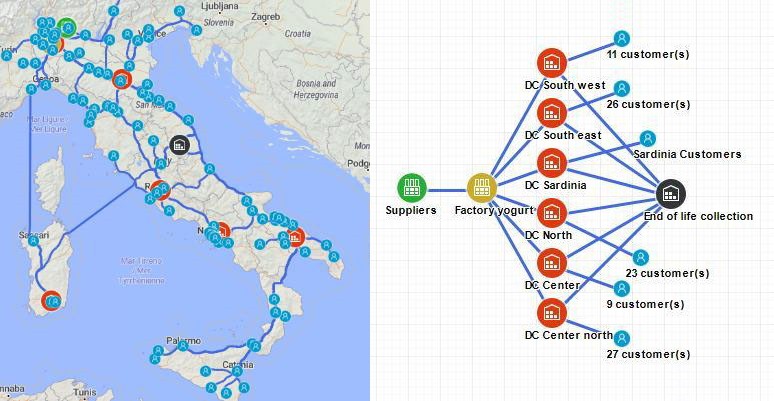

The supply chain in the case study is structured based on examples from the most important companies in the Italian dairy sector, with features appropriately adapted to the simulation context.

Figure 1 — Logical scheme of the yogurt supply chain considered in the study.

The main characteristics of the supply chain model are:

Figure 2 — Supply chain modeling with anyLogistix simulation software.

The simulations carried out on the supply chain model highlighted critical areas for improvement regarding sustainability:

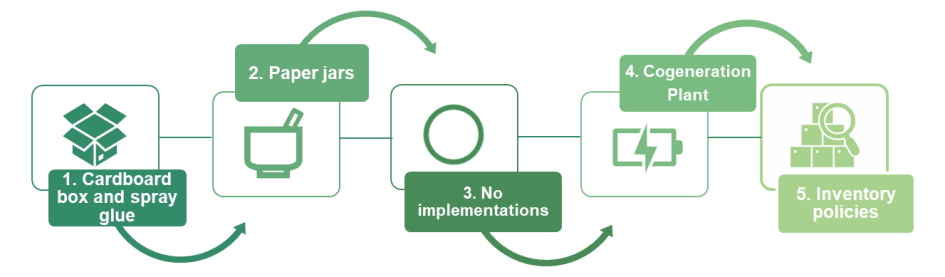

Five sustainability-oriented strategies identified in the development of the ultimate scenarios:

Lastly, a final overall 5-year scenario progressively included all the strategies to observe the overall contribution of the individual strategies over time. In particular, the order of implementation of the strategies is as follows:

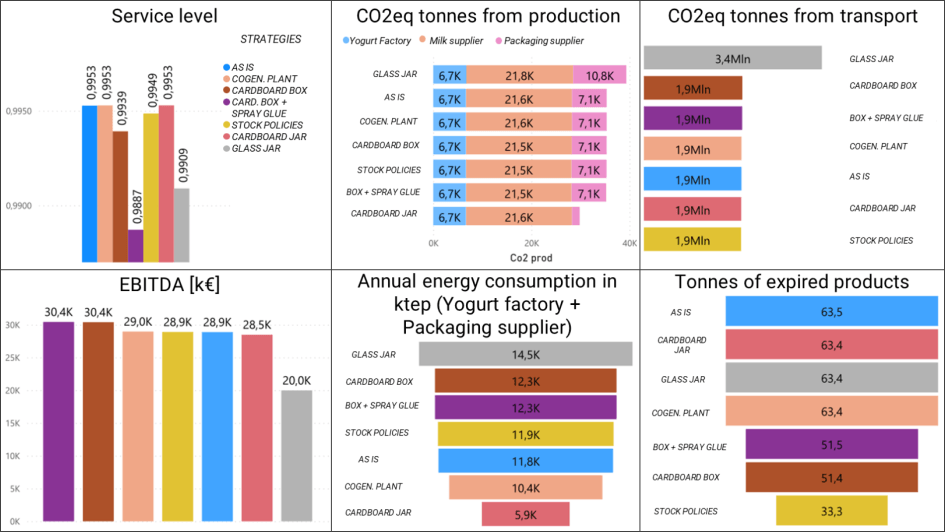

Analysis of the individual scenarios highlights the improvement in environmental performance derived from implementing the strategies described above.

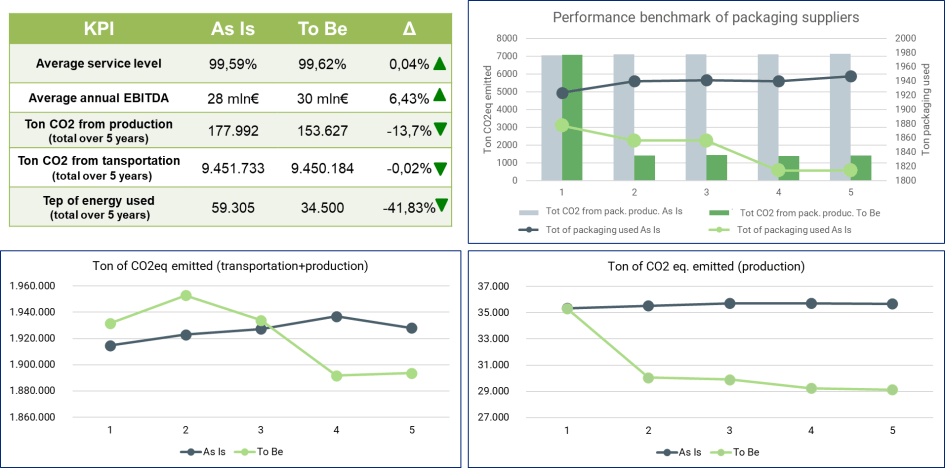

Figure 3 — Benchmark of the principal performance derived from the simulation runs.

In summary, the main findings for supply chain sustainability are:

Each strategy applied individually leads to significant improvements in performance and a more sustainability-oriented supply chain. But, the progressive implementation of strategies over five years gives the best reduction in CO2 emissions, water, and energy consumption.

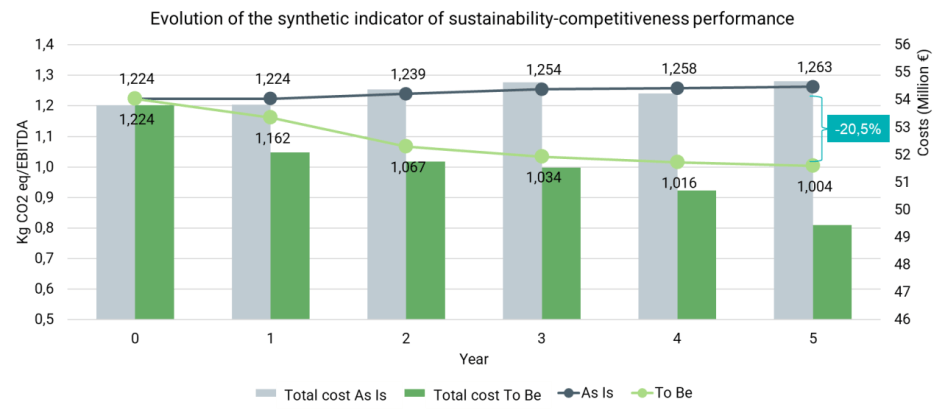

Figure 4 — Evolution of sustainability and competitiveness performance over time.

In particular, after decreasing over the years, in the fifth year, the synthetic indicator that links total emissions with profitability is 20% lower. This is due to a reduction in emissions linked to production at the manufacturer and the packaging supplier, as well as a reduction in supply shipments.

Figure 5 — Detail of some sustainability-related indicators derived from simulation runs.

This case study demonstrates that improvements in sustainability are possible without the need for a major project. That even minor interventions, organized in line with a sustainability strategy, can lead to satisfactory outcomes in the medium to long term. As shown in the different scenarios, a crucial requirement for success is coordinating company strategy and sustainability goals. Once the strategic and environmental sustainability visions are aligned, improving one or more sustainability KPIs, such as reducing CO2 levels or the energy required for processes, can lead to widespread benefits.

Finding and realizing the benefits of these sustainability strategies required a supply chain simulation model. The model allowed accurate assessment of the strategies and their interactions across the supply chain. It showed how it is necessary to adopt a systematic approach to improving a supply chain because the effects of a decision can occur in areas outside those in focus.

Simulation is an increasingly common tool for analyzing and designing supply chain changes. To learn more about how it provides a valuable addition to traditional analytical approaches, download our Supply Chain Simulation and Optimization Overview.