Read also: How-to blog post on last-mile food delivery optimization.

This blog post is partially based on the presentation given at the anyLogistix Conference 2025 by Dr. Pratik Maheshwari from IIM Jammu.

Last-mile delivery has become one of the most critical and costly stages of the supply chain. It directly shapes customer satisfaction and operational efficiency. As e-commerce expands and expectations for speed and flexibility rise, companies are under pressure to find smarter ways to manage this complex process.

In this blog post, we explore the growing challenges of last-mile delivery optimization and how simulation can provide practical solutions. Drawing on recent research by Dr. Pratik Maheshwari from IIM Jammu, we look at key industry obstacles, a case study, and how anyLogistix helps companies to solve last-mile challenges.

Contents:

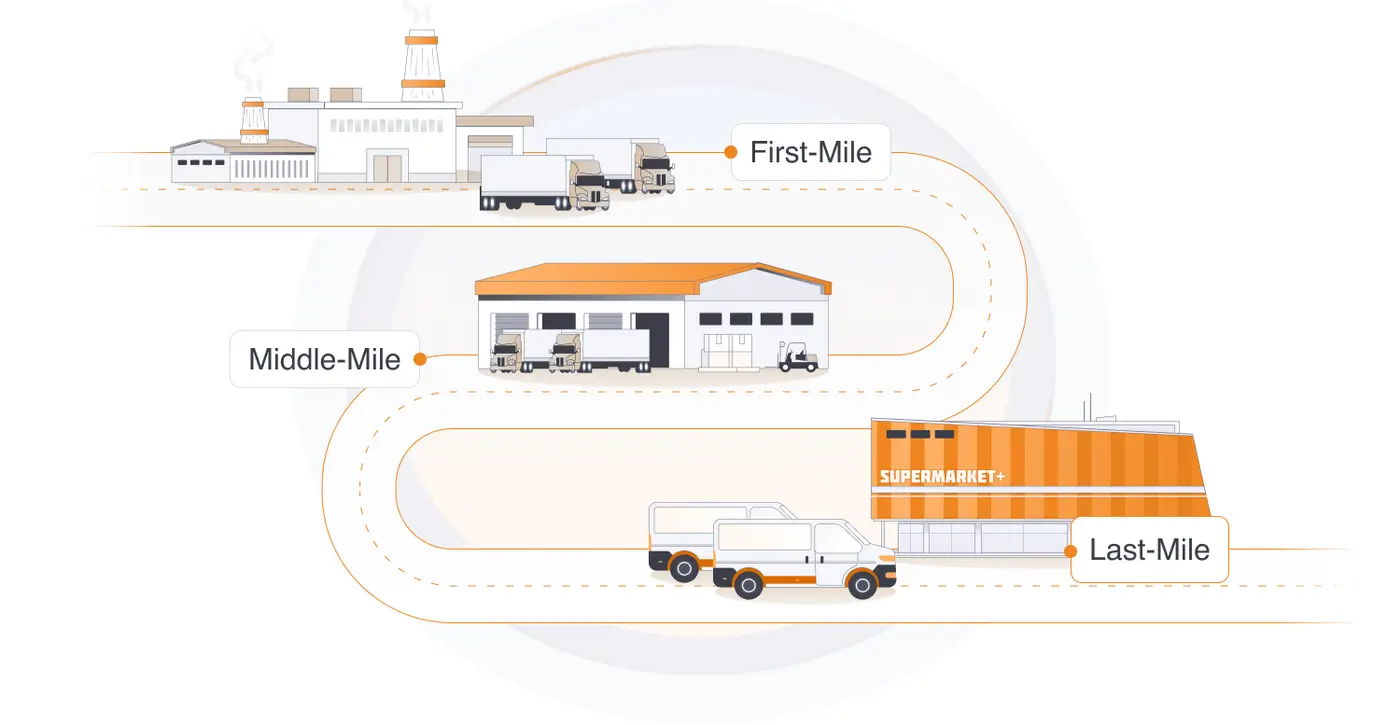

Delivery challenges arise at different stages of the supply chain: first, middle, and last mile. Each stage involves distinct stakeholders. Last-mile delivery refers to the final stage of the supply chain—the movement of goods from a distribution center, warehouse, or transportation hub to the end customer.

This is often the most complex and costly part of the supply chain. Studies show that the last mile can account for up to 53% of total logistics costs, driven by fragmented deliveries, rising customer expectations for speed and flexibility, and the operational realities of urban environments.

First, middle, and last-mile in logistics

With the growth of e-commerce and direct-to-consumer business models, last-mile delivery has evolved from a back-end operational concern into a critical competitive differentiator. Customers now expect:

Another important dimension is reverse logistics, which occurs when customers return products that are damaged, incorrect, or simply do not meet their needs. This adds further complexity to the last-mile process.

Dr. Pratik Maheshwari from the Indian Institute of Management Jammu conducted a study that highlighted a set of recurring barriers that organizations face in managing last-mile delivery optimization:

1. High cost per delivery

The growing volume of small, fragmented orders significantly raises unit costs.

2. Urban traffic congestion

Traffic congestion in densely populated areas causes delivery delays, higher fuel consumption, and greater emissions. At the same time, customers expect faster and more flexible delivery options, making it harder for companies to balance speed with efficiency.

3. Failed deliveries and returns

When products are returned, companies must manage rerouting, pickups, and restocking, all of which increase costs and require additional planning.

4. Last-mile route optimization complexity

Delivery networks must balance traffic patterns, time windows, vehicle capacity, and shifting demand.

5. Infrastructure gaps

Urban restrictions (e.g., limited-access zones or emissions regulations) and compliance requirements add constraints. In rural or underdeveloped regions, poor road networks and inadequate facilities reduce delivery reliability.

6. Lack of real-time visibility

Customers expect real-time tracking and communication, but inconsistent data often leads to uncertainty and frustration.

7. Environmental impact

Frequent, small-scale deliveries contribute to higher carbon emissions, raising sustainability concerns.

8. Lack of qualified drivers

The demand for rapid deliveries has led to a shortage of skilled drivers, impacting the reliability of last-mile services.

Combined, these factors create a complex operating environment in which companies must carefully balance cost efficiency, service quality, and sustainability. These findings underscore the need for robust modeling approaches that can account for uncertainty, trade-offs, and complex interactions in supply chain operations.

Simulation modeling is a powerful tool to address supply chain challenges. Unlike static optimization models, simulation can capture dynamic behavior, disruptions, and real-world constraints. It allows decision-makers to test “what-if” scenarios and observe the impact before committing to costly changes.

anyLogistix is widely used by industry experts as a comprehensive logistics simulation and optimization platform. It enables users to design, test, and refine supply chain networks of any scale, from strategic planning to tactical decision-making.

The recently introduced last-mile optimization experiment in anyLogistix is specifically designed to address route optimization by minimizing total drive time across all delivery routes and improving service levels. It simulates delivery networks in detail, accounts for product and vehicle types, customer time windows, and environmental impact, and tests different routing and network design strategies.

Last-mile delivery optimization experiment in anyLogistix (click to enlarge)

Read also: How-to blog post on last-mile food delivery optimization.

A case study conducted by Dr. Maheshwari highlights how simulation in anyLogistix can help companies tackle last-mile delivery route optimization challenges.

The research involved modeling the supply chain of an Indian manufacturer with one factory, ten distribution centers, and hundreds of customer locations. By simulating different scenarios in anyLogistix, including distribution center closures and changes in inventory policies, the study revealed how network design directly affects service quality and costs.

Operating with fewer distribution centers reduced expenses but harmed service levels, while adding more centers improved reliability at a higher cost. This insight demonstrates the importance of logistics simulation experiments for balancing efficiency and resilience in last-mile logistics.

Watch the full presentation from the anyLogistix Conference 2025, delivered by Dr. Maheshwari from IIM Jammu.

Last-mile delivery is no longer just a logistics concern; it has become a critical driver of customer satisfaction, brand reputation, and overall supply chain performance. Yet it also remains the most expensive and complex part of logistics operations.

With the new last-mile delivery optimization experiment, anyLogistix provides an even more powerful toolkit for companies navigating last-mile delivery challenges. By combining advanced modeling capabilities with practical case studies, organizations can design smarter, more resilient, and more sustainable delivery systems for the future.