What is anyLogistix supply chain software? Discover all the benefits it offers for modeling, simulating, and optimizing complex supply chain operations.

Coca-Cola İçecek launched a supply chain optimization project to address rising transportation costs and growing complexity. Manual data handling and limited expertise made it hard to manage and scale distribution network design across 12 countries.

Together with Phoenix Analytics, they built a digital twin of their supply chain. Through SQL-based automation, teams could generate and run scenarios quickly, supporting a scalable and data-driven supply chain project.

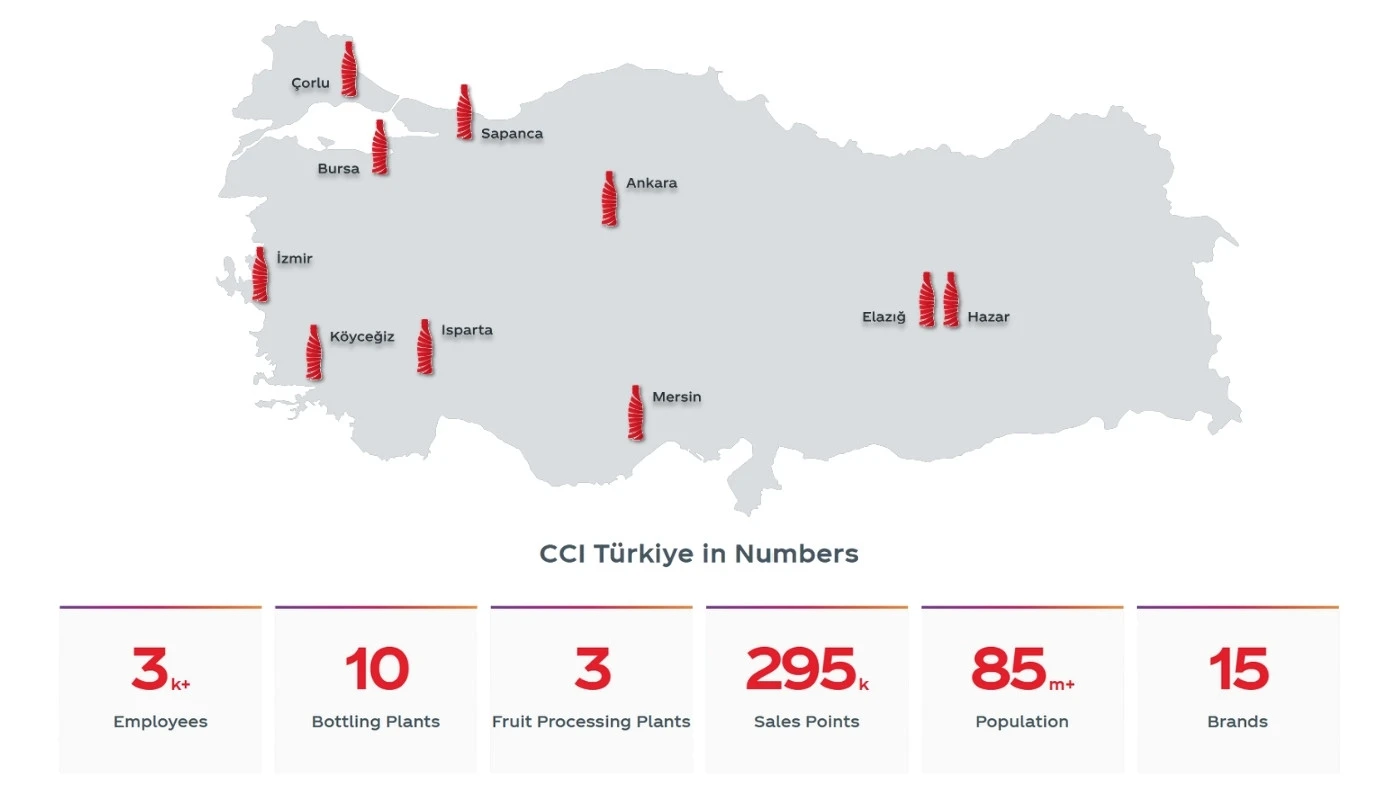

Coca-Cola İçecek (CCI) is one of the largest bottlers in the Coca-Cola system, operating across 12 countries with a highly complex production and distribution network design. In Turkey alone, the company manages over 10 plants, hundreds of SKUs, and more than 200 distributors.

Supply chain network structure in Turkey (Source: Coca-Cola İçecek)

To address rising transportation costs, increasing demand, and the need for better capacity allocation, Coca-Cola İçecek launched a supply chain optimization project in partnership with Phoenix Analytics. The goal was to build a digital twin of the network using anyLogistix and automate scenario generation to support smarter planning decisions.

What is anyLogistix supply chain software? Discover all the benefits it offers for modeling, simulating, and optimizing complex supply chain operations.

The initial challenge stemmed from rising transportation costs and the growing complexity of Coca-Cola İçecek’s supply chain. With each plant having different product capabilities, storage limits, and manufacturing capacities, it became difficult to determine optimal flows, capacity allocations, and sourcing decisions.

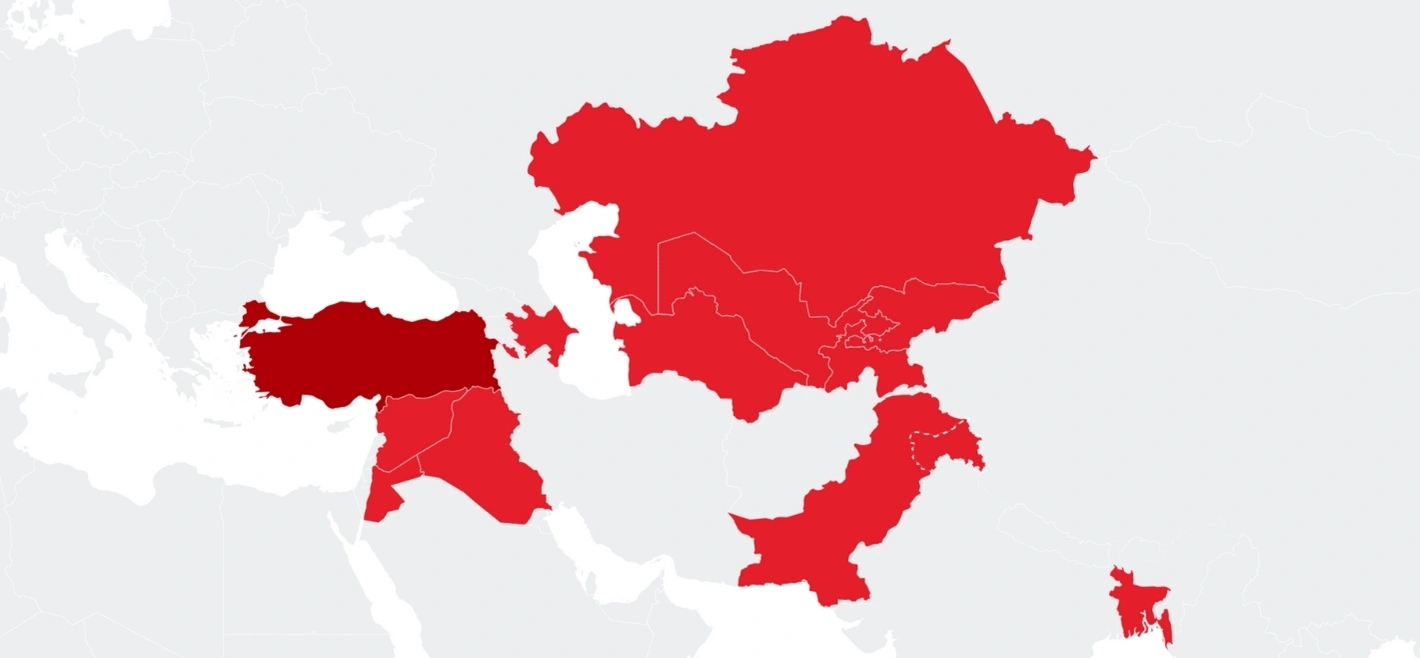

As the company looked to expand its supply chain optimization project beyond Turkey to 11 other countries, the team ran into two major challenges:

Countries covered by Coca-Cola İçecek’s distribution network design (Source: Coca-Cola İçecek)

To enable scalable network optimization across all operations, CCI needed a solution that would streamline data integration, reduce manual effort, and make scenario creation accessible for non-expert users.

To overcome the challenges of manual data handling and limited modeling expertise, Coca-Cola İçecek and Phoenix Analytics designed a fully automated solution centered around anyLogistix. This was a key part of a broader supply chain optimization project, aimed at improving scalability and supporting complex distribution network design across 12 countries.

The core idea was to integrate data directly from CCI’s Google Cloud Platform (GCP) into SQL Server, enabling anyLogistix to generate ready-to-run optimization scenarios with minimal manual input.

Well-known companies around the world are already using anyLogistix in their projects. Take a look at how Danone-Waters increased production capacity by 13% and reduced supply chain costs by 5%.

The integration pipeline consisted of:

Data integration structure in the supply chain optimization project (click to enlarge)

Details of the data integration steps (click to enlarge)

To support scalability, the data was aggregated quarterly in regions with more complex supply networks. This made it possible to run scenarios quickly without losing important model detail.

The collaboration between Coca-Cola İçecek and Phoenix Consulting resulted in a major shift in how supply chain scenarios were built, tested, and scaled. Instead of manually collecting and formatting data across departments, planners got access to fully integrated, up-to-date optimization scenarios that were automatically generated in under 10 minutes.

This supply chain project drastically reduced the operational burden on local teams and allowed them to focus on scenario analysis rather than data preparation. It also opened the door to broader adoption of anyLogistix across CCI’s network, even in countries with limited modeling expertise.

Supply chain optimization project created in anyLogistix software

In addition to operational improvements, the model supported strategic decisions. Planners used the model to evaluate potential investments in new distribution centers, production lines, and molds. This helped ensure that capital planning was guided by data and aligned with long-term distribution network design goals.

Results could be exported to Power BI and other custom reporting tools. This made it easier for planners and executives to access insights, visualize trends, and share findings across teams.

Some of the most notable benefits included:

Most importantly, the project created a reliable, centralized data foundation. It now supports not only anyLogistix experiments but also other business intelligence efforts, paving the way for more agile and data-driven decision-making across the organization.

This case study was presented by Emre Eryilmaz, Phoenix Analytics, at the anyLogistix Conference 2025.

The slides are available as a PDF.